Why I embrace lean -- and you should too

More than an improvement framework, lean embodies public health values

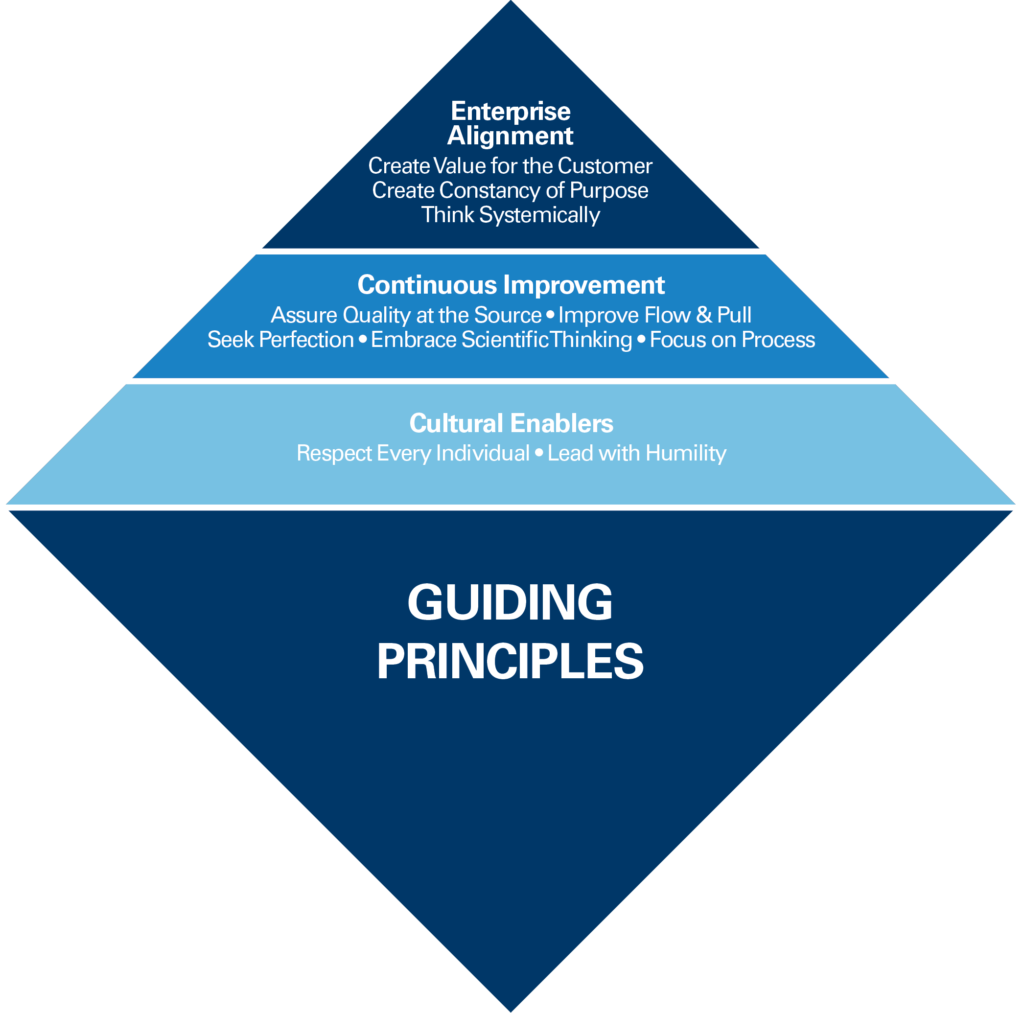

The CDPH Lean OS

To achieve public health accreditation, health departments must deploy a an established continuous improvement framework. The two complementary frameworks we use at the California Department of Public Health are lean and Results-Based Accounability (RBA). In this posting I will focus on lean.

Lean thinking and practice is “systematically developing people to solve problems and consuming the fewest possible resources while continuously improving processes to provide value to community members and prosperity to society.”1

Lean originated in post-World War II Japan when the Toyota Motor Company hired American W. Edwards Deming, professor, statistician, engineer, and quality consultant, to guide their quality transformation to manufacture affordable, high quality automobiles (see https://deming.org). Deming promoted what he called the System of Profound Knowledge that involved developing an understanding of

systems (systems thinking),

people (human psychology),

variation (statistical thinking), and

theory of knowledge creation (eg, Plan-Do-Study-Act).

Toyota experimented, learned, innovated, and improved continuously. This required leadership humility and frontline worker empowerment and ingenuity. Not only did they develop a variety of affordable, reliable, high-quality automobiles, they developed an unique production and management system that took the world by storm, and attracted academicians to study how they did it.2 3

Since then, lean has been adopted by industries worldwide, including in health care to improve patient safety and outcomes, to improve service quality and experience, and to eliminate waste (ie, activities that do not add value from the patient’s perspective). Lean delivers the most value when stakes and expectations are high, or when poor services, defective products, and adverse human outcomes are not acceptable (eg, health and health care inequities).

Lean has also evolved into a leadership philosophy to transform organizational cultures to drive operational excellence (“lean transformation”). The most popular and holistic transformation model is the Shingo Model from Utah State University Shingo Institute. The Shingo Model focuses on 10 Guiding Principles and systems and tools that support and transform culture and drive organizational excellence and results. The Shingo Guiding Principles are divided into 3 dimensions (ie, theory of change):

People — Cultural Enablers (“enable”),

Process — Continuous Improvement (“improve”), and

Purpose — Enterprise Alignment (“align”).

I cover the Shingo 10 Guiding Principles in the second half of this article. Based on these 10 Guiding Principles and my public health leadership practice and experience (eg, responding to COVID-19 pandemic), I adapted and prioritized the following 8 lean principles:

Respect every individual (humility and trust),

Lead with humility (humble leadership),

Improve continuously (aka, “seek perfection”),

Embrace scientific thinking (eg, PDSA),

Measure what matters (Objective & Key Results),

Eliminate waste and undesired variability,

Respond and adapt with speed and agility, and

Create value for the customer.

These 8 principles overlap with the Shingo Principles and together, the 13 principles, make up the CDPH Lean Principles (Table 1) and they should apply to all persons, teams, and organizations that deliver public health or health care services. In fact, I believe they should apply to any human service organization. These CDPH Lean Principles are my playbook for “Becoming the best at getting better.”

In lean, your people and your customers are the most important. The foundation is building strong, trusting relationships, fostering openness, and creating an environment where everyone feels valued and empowered to contribute. This can only occur by respecting every individual and leading with humility. To learn more see “Leadership is getting results in a way that inspires trust (part 2): A common sense framework for building and extending trust” (Team Public Health).

The principle “Measure what matters” is applying the leadership goal-setting best practice of using Objective and Key Results (OKRs) for your most important strategic initiatives. I expect my staff to be able to answer these two OKR questions: “For your top strategic priorities,

What do you/we want to accomplish? (Objectives). Good Objectives are significant, concrete, action-oriented, and inspirational.

How do you/we measure progress and success? (set of Key Results). Good Key Results are specific and time-bound, aggressive yet realistic, and measurable and verifiable.”

OKRs was popularized by John Doerr’s book “Measure What Matters: How Google, Bono, and the Gates Foundation Rock the World with OKRs.”4 To learn more about OKRs read my blog post Why leaders embrace OKRs — and you should too.

Here is the 2-page guidance I provide to my staff on how to brief me.

A value stream is a coordinated and aligned set of activities that create value for a customer (product, service, or changes to policies, systems, or environments). For human beings the most important value stream is the human life course with a focus on early development of children, adolescents, and young adults. In public health we deploy the Shingo Principle of “Assure Quality at the Source” the following program types:

WIC (Special Supplemental Nutrition Program for Women, Infants, and Children)

Maternal, child, and family health

Home visiting

Childhood lead poisoning prevention

Youth mental health

and many more

With reflection you will discover that the Lean Principles embody and deploy public health values in a way that is practical and inspiring. For me, this discovery was a very profound and underscores why I am so enthusiastic about lean for all health systems, but especially for public health.

The Shingo Model — “Transforming culture to drive excellence”

The Shingo Model has five components. First, the 10 Guiding Principles are the basis for building a lasting culture and achieving organizational excellence. Second, a system is a collection of tools working together to accomplish an intended outcome. Third, tools are solutions or methods that accomplish specific tasks. Lean is well known for its tools to eliminate waste in processes. Fourth, a result is a measurable outcome, either successful or unsuccessful, that results from the implementation of tools and systems. And fifth, culture is all the behaviors within an organization.

Shingo Guiding Principles

The Shingo Guiding Principles are ten principles that are the basis for building a sustainable culture of enterprise excellence. In the Guiding Principles diamond, the principles are divided into the three dimensions or theory of change:

People — Cultural Enablers (“enable”),

Process — Continuous Improvement (“improve”), and

Purpose — Enterprise Alignment (“align”).

The first dimension in the Guiding Principles consists of the Cultural Enablers principles that focus on the foundation of an organization: its people.”

Respect every individual,

Lead with humility,

The second dimension in the Guiding Principles addresses processes. In a culture of Continuous Improvement, the focus must not be only on quality or cost. The organization must incorporate all aspects of value as perceived by the customer: innovation, quality, cost, flexibility, quick delivery, and a comprehensive view of environment, health, and safety.

Seek perfection, (see note and footnote5)

Embrace scientific thinking,

Focus on process,

Assure quality at the source,

Improve flow and pull,

NOTE: For organizations that deliver high-stake services, such as health care and public health, “seeking perfection” is the mindset and intention that every individual, every time, should receive high-quality services that are safe and equitable. Recognizing that humans are not perfect, we seek to design processes and systems to achieve safety, quality, and equity. Put another way, think about your personal experience and expectations when you receive a vaccine injection, undergo a medical procedure, or board an airplane. You expect your provider and your pilot to have this mindset and intention every single time. CAUTION: This principle can be misinterpreted as “seeking perfectionism.”

The third dimension in the Guiding Principles focuses the purpose of an organization. To achieve enterprise excellence, an organization must effectively align every value stream with its values, goals, and mission (Enterprise Alignment).

Think systemically (“systems thinking”),

Create constancy of purpose, and

Create value for the customer.

Lean resources

Below are some resources to support your lean journey. In future postings I will dive into specific lean concepts, methods, or principles.

Lean Guidance for Briefing Director (me) - PDF

Lean Shingo Model: https://shingo.org/shingo-model/

Lean for health care: https://createvalue.org/

Lean Enterprise Institute: https://lean.org

Appendix - Clarifying terminology that is applied to inputs, processes, outputs, and outcomes

Objectives and Key Results can be designed and measured for inputs, processes, outputs, and outcomes (Table 2). For example, in a startup phase of a project, the OKRs may focus on inputs (eg, securing funding, recruiting staff). Lean practice can deploy OKRs and work from this table.

The confusion occurs because RBA uses the term “performance measures” for Key Results from enumerable populations (eg, program, agency, or service system) or uses the term “population indicators” for geographically defined populations (eg, city, county, state).

Footnotes

Lex Schroeder. Public Service: Lean’s Next Frontier? Lean Enterprise Institute, 2014.

Womack, James P., and Daniel T. Jones. Lean Thinking: Banish Waste and Create Wealth in Your Corporation. 1st Free Press ed., rev.Updated. New York: Free Press, 2003.

Womack, James P., Daniel T. Jones, and Daniel Roos. The Machine That Changed the World: The Story of Lean Production - Toyota´s Secret Weapon in the Global Car Wars That Is Revolutionizing World Industry. 1. paperback ed. London: Free Press, 2007.

Doerr, John. Measure What Matters: How Google, Bono, and the Gates Foundation Rock the World with OKRs. New York: Portfolio/Penguin, 2018.

“Perfection is an aspiration not likely to be achieved, but the pursuit of perfection creates a mindset and culture of continuous improvement. What is possible is only limited by the paradigms through which we see and understand the organization’s current reality” (source: The Shingo Model booklet available from: https://shingo.org/shingo-model/).